Building Solutions for the Construction Industry

Engineered Wood Products

SBSI offers complete engineered wood solutions for your project. Stop by or contact us online for more information.

Laminated Veneer Lumber (LVL)

LVL is a widely used structural composite lumber product. It is produced by bonding thin wood veneers together in a large billet so that the grain of all veneers is parallel to the long direction. The LVL billet is then sawn to desired dimensions depending on the end-use application. Because LVL is made with scarfed or lapped jointed veneers, LVL is available in lengths far beyond conventional lumber lengths.

Popular LVL applications include headers and beams, hip and valley rafters, scaffold planking, and the flange material for prefabricated wood I-joists

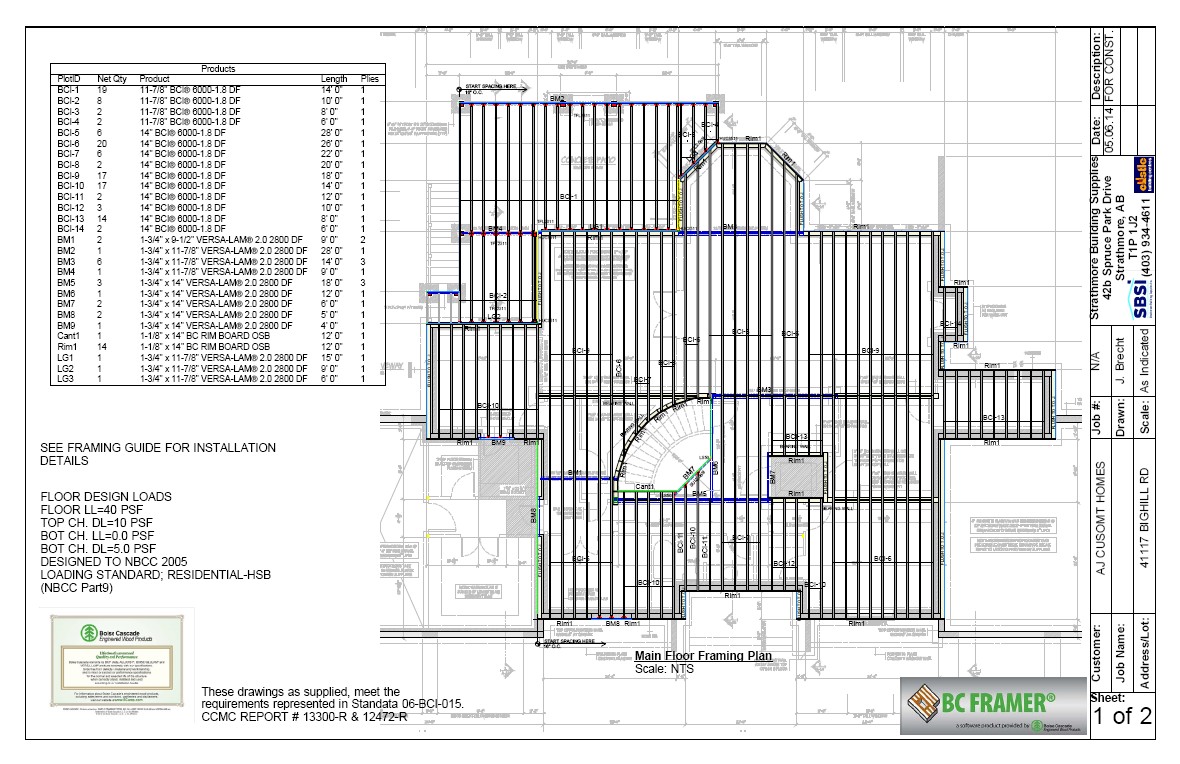

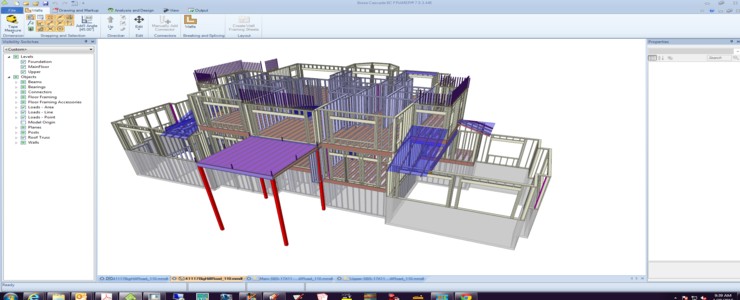

I-Joist Basics

I-joists are strong, lightweight, "I" shaped engineered wood structural members that meet demanding performance standards. I-joists are comprised of top and bottom flanges, which resist bending, united with webs, which provide outstanding shear resistance. The flange material is typically laminated veneer lumber (LVL) or solid sawn lumber, and the web is made with plywood or OSB. The robust combination of structural characteristics results in a versatile, economical framing member that is easy to install in residential and light commercial projects

Rim Board Basics

APA Performance Rated Rim Board is a specially designed component, designed to work in concert with the foundation and floor framing members to deliver a complete engineered wood solution. With high strength, dimensional stability, and structural reliability, Rim Boards perfectly match the depth of wood I-joists and offer highly predictable performance and consistent quality. APA Performance Rated Rim Board may be manufactured with plywood, oriented strand board (OSB), glued laminated timber (glulam), or laminated veneer lumber (LVL) and is available in lengths up to 24 feet, depending on the product used

Glulam Basics

Glued laminated timber, or glulam, is a highly innovative construction material. Pound for pound, glulam is stronger than steel and has greater strength and stiffness than comparably sized dimensional lumber. Increased design values, improved product performance, and cost competitiveness make glulam the superior choice for projects from simple beams and headers in residential construction to soaring arches for domed roofs spanning more than 500 feet.

Learn more about Engineered Wood

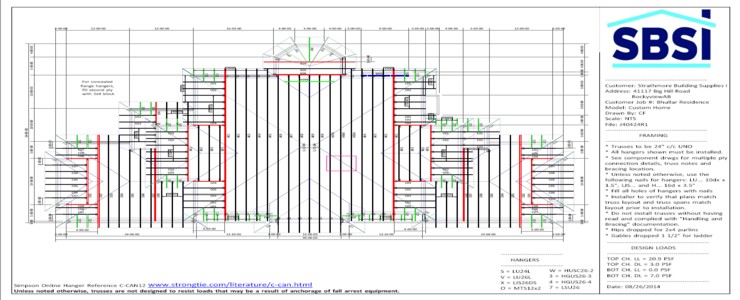

Roof Truss Basics

Roof trusses are pre-fabricated, triangulated wood structures, which are built in a factory and carefully designed to carry the load of your home's roof to the outside walls. Then they are shipped to your construction site and installed using a crane after the home's walls have been framed. Nearly 80% of new homes constructed today use pre-manufactured roof trusses instead of traditional rafters to support the roof.

The key benefits of using pre-fabricated roof trusses are cost savings and construction speed. They are also increasingly popular because they allow great flexibility and complexity in roof design

Learn more about Roof Trusses